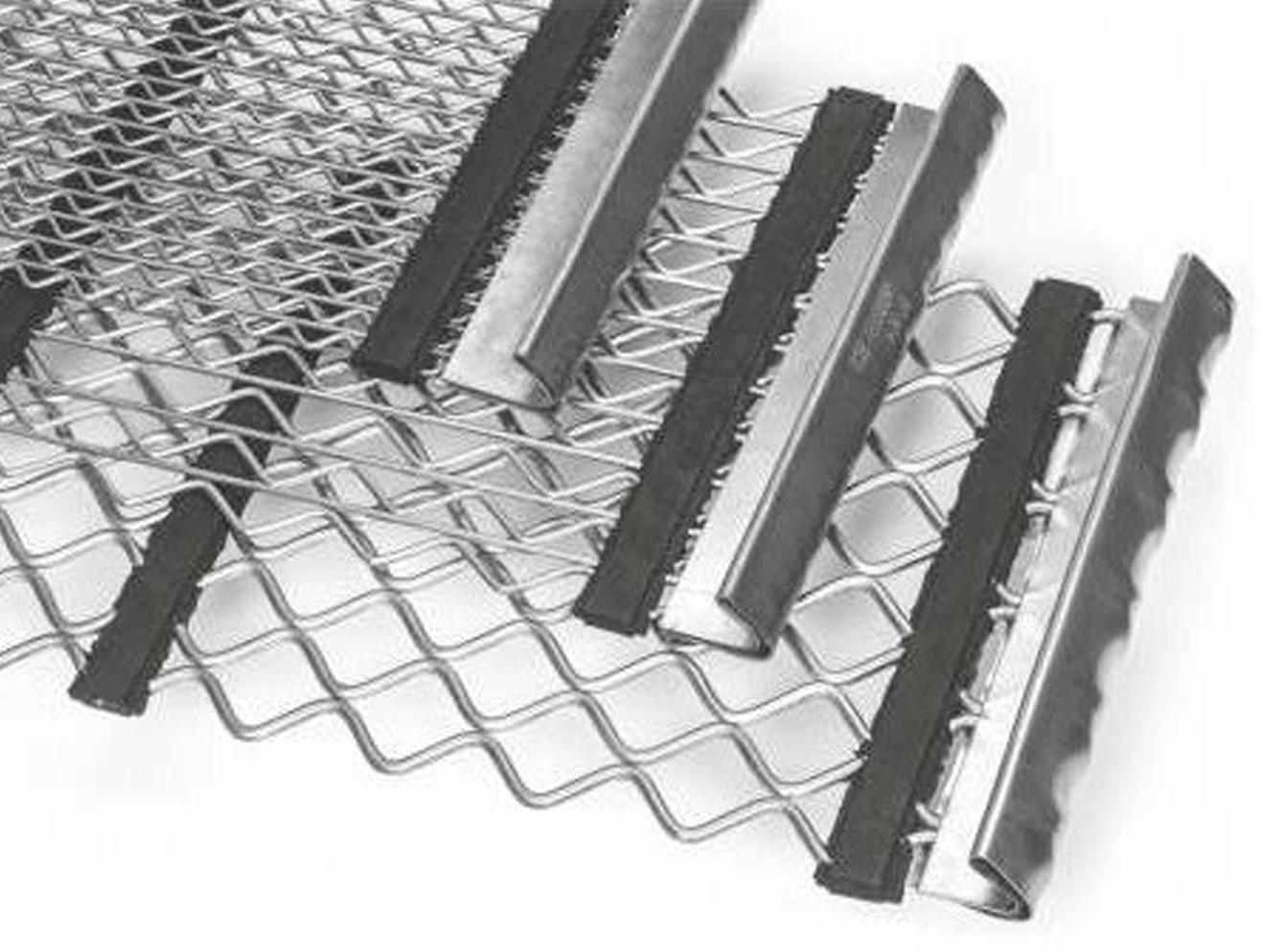

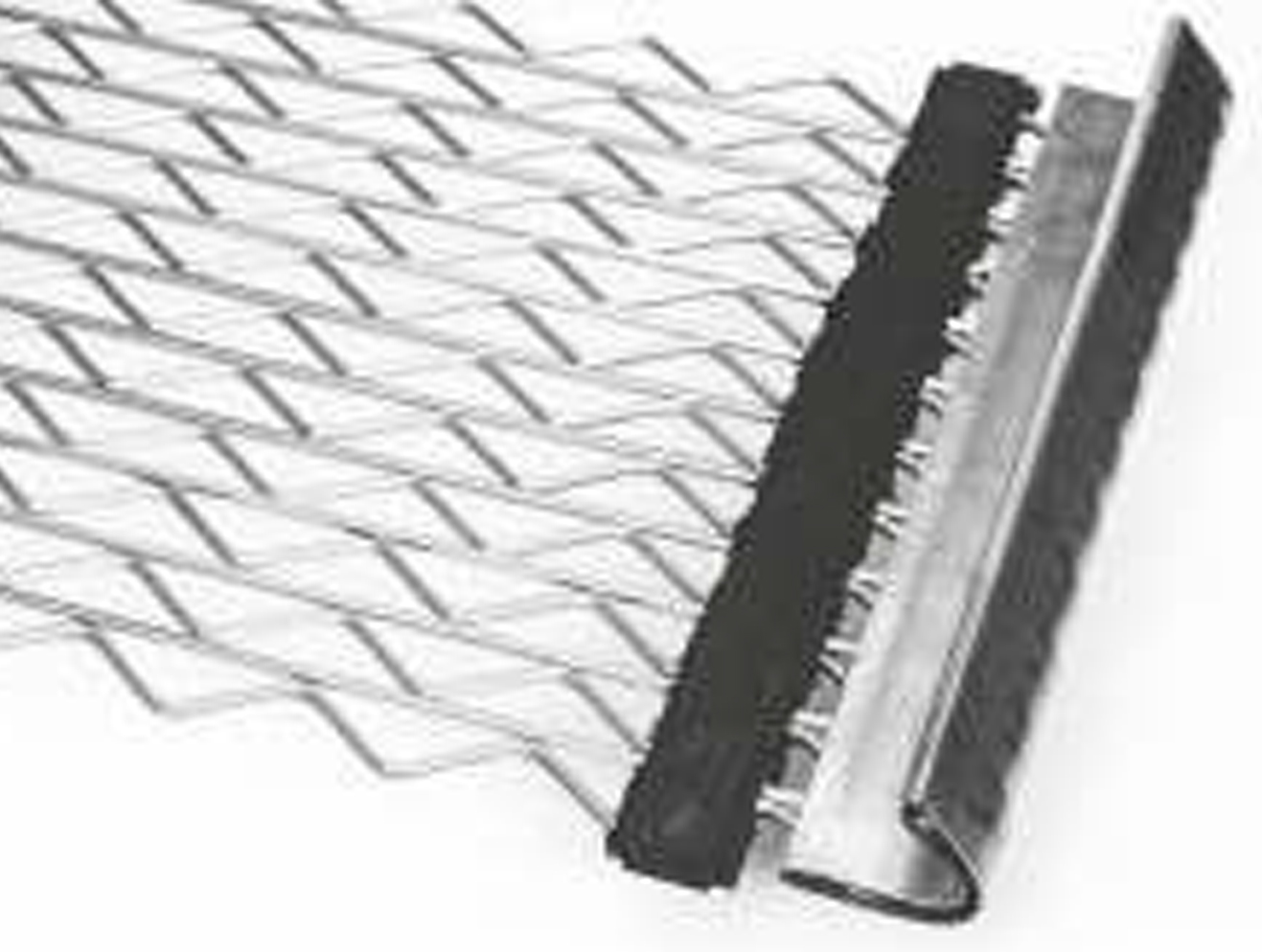

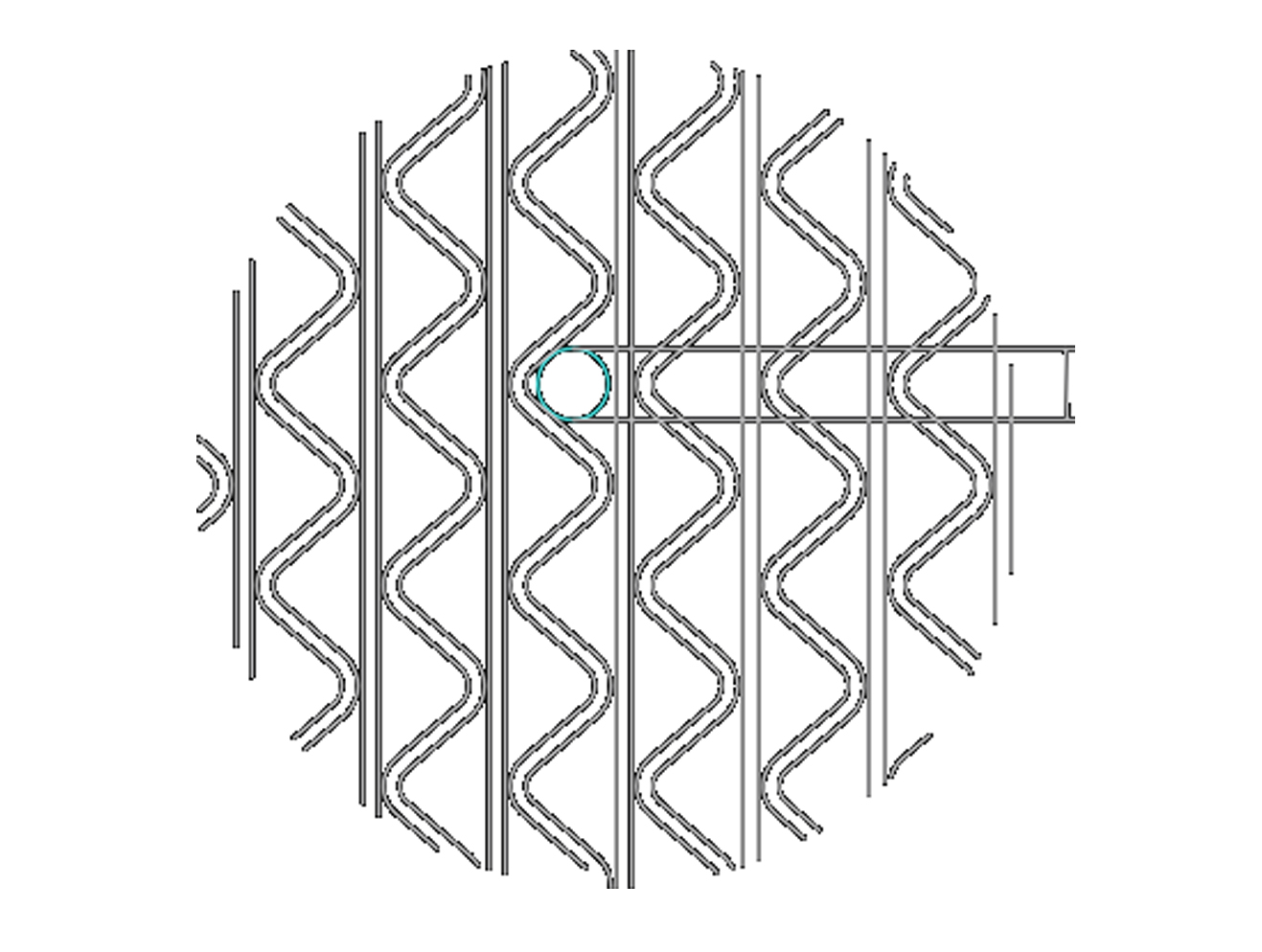

Harp Wire Mesh is generally used to grade hygroscopic particles or grains that tend to accumulate around mesh openings/spacings. The wires are literally woven, forming a wave pattern with transverse wire clusters holding the wires together to provide excellent mesh spacing for clog free screening/sieving. trusted since ages.

We use best quality in Spring Steel / High Carbon Steel, Stainless Steel and MS wire. to manufacture our unparalleled Harp Wire. Harp Wire Mesh offer very fine and accurate meshes of stainless steel. We have specifically designed these Harp Wire mesh for various household purposes and industrial usage.

Harp Wire Mesh have been manufactured keeping in view the valid standards of Pakistan and global market. We are destined for reaching new heights of quality and prosperity. Durability and cost effectiveness are the additional advantages of our Harp Wire Mesh

| B.S.S | A.S.T.M. | I.S. | MICRONS |

| (410/1969) | (11-70) | (469/1972) | |

| 4 | 5 | 4.00mm | 4000 |

| 5 | 6 | 3.35mm | 3353 |

| 6 | 7 | 2.80mm | 2812 |

| 7 | 8 | 2.36mm | 2411 |

| 8 | 10 | 2.00mm | 2057 |

| 10 | 12 | 1.70mm | 1680 |

| 12 | 14 | 1.40mm | 1405 |

| 14 | 16 | 1.18mm | 1204 |

| 16 | 18 | 1.00mm | 1003 |

| 18 | 20 | .850mm | 850 |

| 22 | 25 | .710mm | 710 |

| 25 | 30 | .600mm | 600 |

| 30 | 35 | .500mm | 500 |

| 36 | 40 | .425mm | 420 |

| 44 | 45 | .355mm | 355 |

| B.S.S | A.S.T.M. | I.S. | MICRONS |

| (410/1969) | (11-70) | (469/1972) | |

| 52 | 50 | .300mm | 300 |

| 60 | 60 | .250mm | 250 |

| 72 | 70 | .212mm | 210 |

| 85 | 80 | .180mm | 180 |

| 100 | 100 | .150mm | 150 |

| 120 | 120 | .125mm | 120 |

| 150 | 140 | .106mm | 105 |

| 170 | 170 | .090mm | 90 |

| 200 | 200 | .075mm | 75 |

| 240 | 230 | .063mm | 63 |

| 300 | 270 | .053mm | 53 |

| 350 | 325 | .045mm | 45 |

| 400 | 400 | .037mm | 37 |

| 500 | .025mm | 35 |